Product gallery

1

2

3

4

1

Speed-up your microplate work

The CAPPTronic offers standard pipetting, multidispense, mixing, sequential aspiration (for dilution) and sequential dispensing.

2

Long-life lithium battery

3

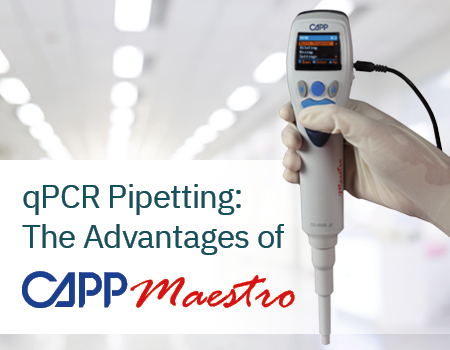

Ultimate performance

A very lightweight electronic pipette, run by a stepper-motor. Designed to be a reliable tool for users who want to optimize their workflow without compromising accuracy and precision.

4

Wide tip compatibility

Compatible with the most common brands of pipette tips available in the market.